Our multi-functional automatic blister packing machine has the advantages of innovative design, the contact part of the drug is made of stainless steel and high grade aluminum alloy materials,Package can use aluminum-plastic or aluminum-aluminum; applicable to the pharmaceutical, food, health care products packaging industry and medium-big size hospitals for plain tablets, capsule, sugar coated tablets, capsules, tomato sauce, chocolate sauce, honey, face cream and so on.

The machine is new innovating designed by our machine which is widely for packaging of medicine, which of function are reached to the advanced level of China. It is used for tablet, capsule, pill, honey pill, candy, liquid, paste, disposable syringe in regular and irregular shaped Alu/PVC, Alu/Alu or Paper /Alu in the field of pharmaceutical, health product, foodstuff, cosmetic, medical instrument etc.

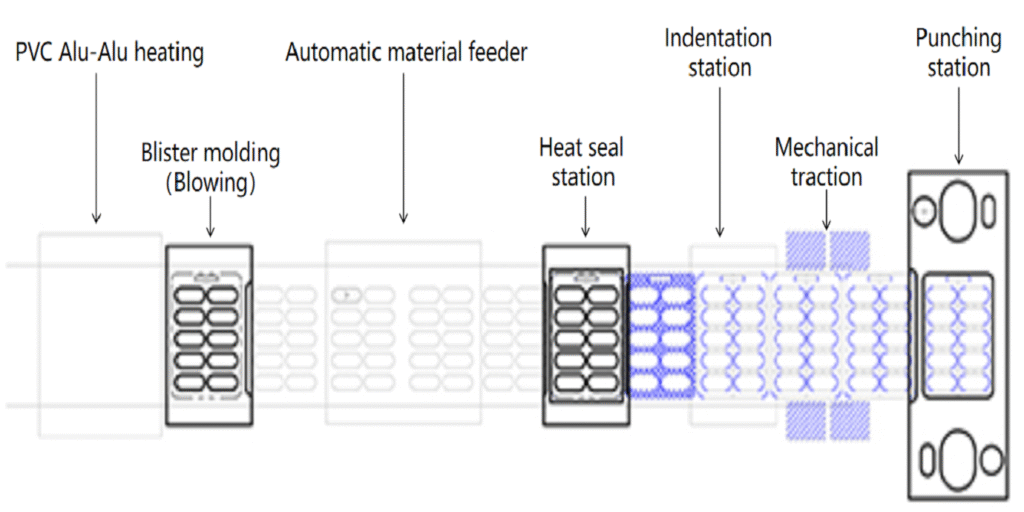

PVC loading

Heating sealing, Waste rewinding

Forming

Note:

The seller makes guarantee that the machines are new (or unused) and the guarantee period will be 12 (twelve) months, which starts from the date of the machine’s arrival. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice, with one condition that the freight will be affected by the buyer. If required for more spare parts additionally, the seller will arrange to have them got ready within 10 days on the buyer’s account.

Installation will be done by our technician (if needed) after the machine placed at the site. All the utilities like water electrical will be connected by you. We shall depute our technicians after receiving your confirmation for the pre installation readiness. All our expenses including round –trip air ticket to the nearest airport, local conveyance to your factory ,Lodging & Boarding expense shall be paid by you. In case the stay of our technician, the service charge at US$100 per day will be charged extra.

WhatsApp:+86 18057763771

Email :[email protected]

No.672 Development Zone Road, Dongshan Street, Ruian City, Zhejiang China.

Whatsapp:18057763771

WhatsApp:+86 18057763771

Email :[email protected]

No.672 Development Zone Road, Dongshan Street, Ruian City, Zhejiang China.

Copyright © 2025 Yabo Machine Company