Blister packaging is common in many industries, especially pharmaceuticals. It protects products and offers visibility.

1. What is Blister Packaging?

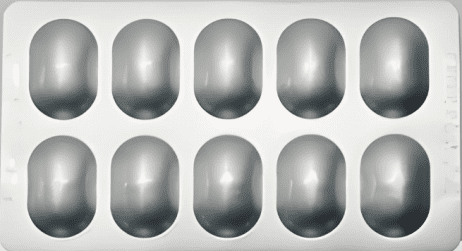

Blister packaging features a cavity or pocket, called a “blister.” It is made from thermoformed plastic and holds the product securely. A backing material, like paperboard or foil, seals the blister. This creates a clear package that lets consumers see the item inside.

2. Why Choose Blister Packaging?

Blister packaging has many benefits.

In pharmaceuticals, it protects medications from moisture, oxygen, light, and contaminants. This keeps drugs effective and safe during their shelf life.

It also offers convenience. Single-dose dispensing reduces dosing errors, which is helpful for patients with complicated medication routines. The separate compartments help patients manage their medicines better.

Blister packs are compact, lightweight, and easy to store. This is good for both manufacturers and consumers.

From a marketing angle, the clear packaging showcases the product. It also has space for important details, such as usage instructions and expiration dates.

3. The History of Blister Packaging

Blister packaging began in the mid-20th century as a solution for consumer goods. In the 1950s, the pharmaceutical industry saw its potential. Early designs used basic plastic and manual processes.

With advancements in materials and technology, blister packaging improved. New materials, like polyvinylidene chloride (PVDC), were introduced. Manufacturing became more automated, leading to better quality and cost-effective packs.

4. Types of Blister Packaging in the Pharmaceutical Industry

Several types of blister packaging are commonly used in pharmaceuticals:

Aluminum-Plastic (Al-Plas) Blister Packaging: This popular type has a plastic blister and an aluminum backing. The aluminum protects against moisture and light. It is cost-effective for tablets and capsules.

Aluminum-Aluminum (Al-Al) Blister Packaging: This type uses two aluminum layers, providing excellent protection against environmental factors. It is ideal for sensitive medications but costs more than Al-Plas.

Aluminum-Plastic-Aluminum (Al-Plas-Al) Blister Packaging: A hybrid design that combines Al-Plas and Al-Al benefits. The middle plastic layer adds flexibility, while the outer aluminum layers enhance protection. This is used for medications needing high protection and some flexibility.

5. Blister Packaging in Other Industries

Blister packaging isn’t just for pharmaceuticals. In cosmetics, it packages items like lipsticks and perfumes, protecting them and enhancing their shelf appeal.

In electronics, it safeguards delicate components like circuits and resistors. The packaging prevents damage and electrostatic discharge.

For toys and small hardware, blister packaging displays and protects products. It lets consumers see items clearly, making it easier to choose.

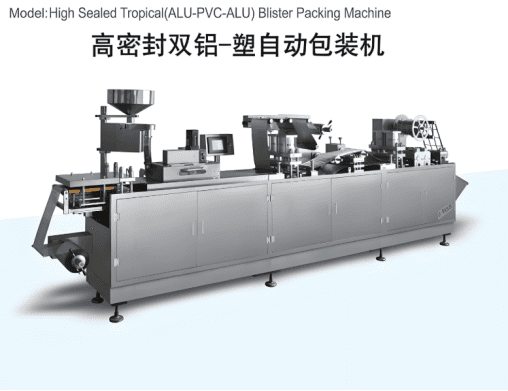

6. Production Process of Blister Packaging Machines

The production of blister packs involves several steps:

Plastic Film Forming: A plastic film, often PVC or PET, is fed into the machine. It heats and forms into blisters using molds through vacuum or pressure forming.

Product Feeding: Once formed, products are placed into each cavity. Automated systems may count and drop tablets or capsules accurately.

Aluminum Foil Heat Sealing: A sheet of aluminum or backing material is placed over the blister. Heat and pressure seal the foil to the blister edges.

Finished Product Punching: The sealed sheet is cut into individual units using punching tools. These blister packs are then ready for packaging and sale.

7. Conclusion

Blister packaging is vital in modern packaging across various industries. In pharmaceuticals, it protects medications, boosts patient compliance, and ensures quality. Its evolution reflects ongoing efforts to meet diverse product needs.

In sectors like cosmetics, electronics, toys, and small hardware, blister packaging provides unique advantages in protection, display, and convenience. As technology advances, blister packaging will likely continue to adapt, meeting new product requirements while remaining a key solution.